The Art of Non-Alcoholic Spirits

blog

For decades, spirits and cocktails have fostered a culture of craft, connection, and celebration. But over time, cocktail culture has evolved far beyond the buzz!

Written by Randy Allender, Owner & Manager, R Allender Consulting

There's more to building a distillery than cobbling together four walls, a ceiling, and a few stills. If you want to build a distillery-and do it the right way-there are a number of details to consider, many of which involve safety, regulations, and operational efficiency.

This is a complicated topic, and every project is unique, but there are a few simplified, general guidelines I propose for distillery design in the US. Please note that any advice stated here should be reviewed and verified by those qualified to do so in your part of the world.

Any alcohol production operations such as distilling, processing and gauging tanks, barrel filling and dumping, and filtering processes should be contained together as you map out your distillery. Why? Because hazardous operations such as these will generally require electrical equipment, fixtures, and other devices to be properly rated for use in a hazardous or explosive environment.

Outfitting a building or area within a building to be compliant can be expensive; so if you scatter the equipment for processes noted earlier throughout your facility, then you run the risk of having every square foot of your building classified as requiring those expensive electricals to be brought into compliance. Plan smart, and you can save yourself a lot of money and headache by segregating those alcohol production spaces away from other non-hazardous components of the business.

Likewise, the International Building Code (IBC) and subsequently most state building codes stipulate that if a building or area of a building has a total amount of Class 1B or 1C flammable liquid exceeding 240 gallons (sprinklered) or 120 gallons (non-sprinklered), it will likely be classified H-3 (high hazard). Most distillery products fall into Class 1B or 1C flammable liquids (being above 40 proof). Please note that this is based upon my limited knowledge of the IBC, so you'll need to enlist a qualified architect or building design firm; however, the primary message here is that you will need to account for safety-particularly fire safety-in your distillery design.

This is true throughout the project. For example, if you're going to be milling your own grain, then that can impose hazardous requirements, too. Depending on a number of factors (such as the type of mill or whether your mill is contained inside certain buildings), you may need to have engineered "blow-out" panels designed and installed as part of an exterior wall. This is another significant design, cost, and safety consideration-but luckily one where you have other options. If there is a safe and appropriate place for it, you can explore the possibility of placing your mill outdoors, or perhaps opting to purchase pre-milled grain instead.

In most instances, bottling in general is not required to be in an area rated as a hazardous location; however, there is an area near the actual filler and between the filler and where a cap or cork is installed to close the container that should be respected, electrically. This is based on the DISCUS' "Recommended Fire Protection Practices for Distilled Spirits Beverage Facilities." I became familiar with these guidelines during my years at Jim Beam. I would strongly encourage you to review the DISCUS website and consider obtaining the latest version of this document prior to building your distillery.

If you are aging spirits in barrels, I always recommend a separate storage structure to house that precious cargo. I really hate walking into a micro-distillery only to find the entire wealth of barrels stored just a few feet away from their distilling equipment.

Think about it. If your distillery were damaged by a fire or other disaster, the barrels would still be safe in sound if stored in a separate structure, providing you with valuable inventory to bottle and sell while you repair your distillery. If housed altogether, you run the risk of being put out of business.

The same can be said of the "non-hazardous" parts of your operation. There's no need to keep them in the same space as your alcohol production or warehousing-again, if anything happens in or around one structure, you won't be forced to start from scratch with your facility.

"Non-hazardous" operations include mash cooking and fermenting, which either produce zero alcohol or, in the case of fermenters, do not result in enough alcohol to be classified as flammable. Other elements that support the general operation of a distillery (think boiler room, water treatment equipment, air compressors, electrical panels, motor controllers, etc.) should also live separately from your alcohol production area or building, as with labs, production offices, maintenance shops, and employee facilities (break rooms and restrooms).

Finally, any general offices, retail areas, event spaces, and the like ideally should be housed in a separate structure (or structures) and hopefully all at ground level-this just makes the design and construction less expensive for you, overall.

Most importantly, all areas should have properly designed and installed sprinklers.

There's much to consider regarding distillery design, but don't overlook the simple things either. Here's a few examples:

Best distillery design really can't be accomplished until all equipment has been determined. Knowing what you are going to produce, how much, and what is the expected production schedule is imperative. Only select alcohol production equipment fabricated by reputable manufacturers.

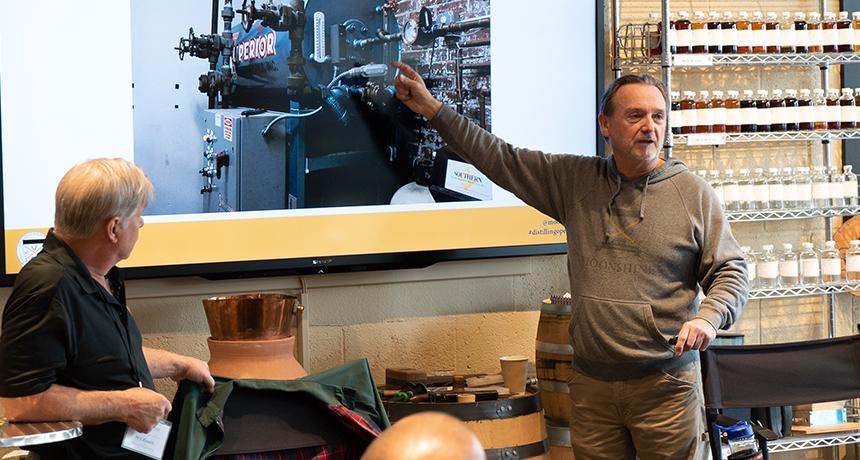

If you're interested in taking a deeper dive into distillery design, I recommend signing up for a 6-Day Distiller Course or Distilling Operations Course at Moonshine University.

Interested in advancing your knowledge of distilling and the spirits industry? Check out Moonshine University's upcoming courses to learn from the best in the business.

Written by Randy Allender, Owner & Manager, R Allender Consulting

Randy retired from Jim Beam in July 2013 after 24 years of service and with 40+ years of experience in various industries. He opened R. Allender Consulting to provide technical advice to those wishing to build a distilled spirits plant, and continues to mentor students of Moonshine University's 6-Day Distiller Course and Distilling Operations Course. He shares a wealth of knowledge from his expertise in distillery procedures and operations including in areas like mechanics, OSHA workplace requirements, electrical control systems, environmental requirements, and more.

Related Content

Understanding The Basics of Distillery Boiler Water Treatment

blog

For decades, spirits and cocktails have fostered a culture of craft, connection, and celebration. But over time, cocktail culture has evolved far beyond the buzz!

blog

Those that are familiar with the process of crafting distilled spirits may also be familiar with the 10 common congeners that are created during fermentation, and honed during the distillation run. Each congener has its own distinct personality, rendering unique tastes and aromas to the finished spirit.

blog

So, you want to start distilling with freshly milled grain. Maybe you're tired of paying top dollar for the pre-milled stuff from the malt distributor, and you're ready to invest in the quality, efficiency, and bulk pricing that comes with milling your own whole grain. But where do you start?